Training Courses in Concrete Petrography

Attending a training course in concrete petrography may be the way to quickly improve your company’s market position. We offer pre-defined courses or tailor a course to your needs at the Danish Technological Institute in Copenhagen, Denmark.

Training Courses in Concrete Petrography

CXI offers pre-defined courses or tailor a course to your needs either to be held at your own laboratory or in Copenhagen, Denmark.

Do you have a lot of jobs in the field of concrete analysis but not the right trained and experienced personnel sound familiar to you? Attending a training course in concrete petrography may be the way to quickly improve your company’s market position. We offer pre-defined or tailored courses to be held at the Danish Technological Institute in Copenhagen, Denmark.

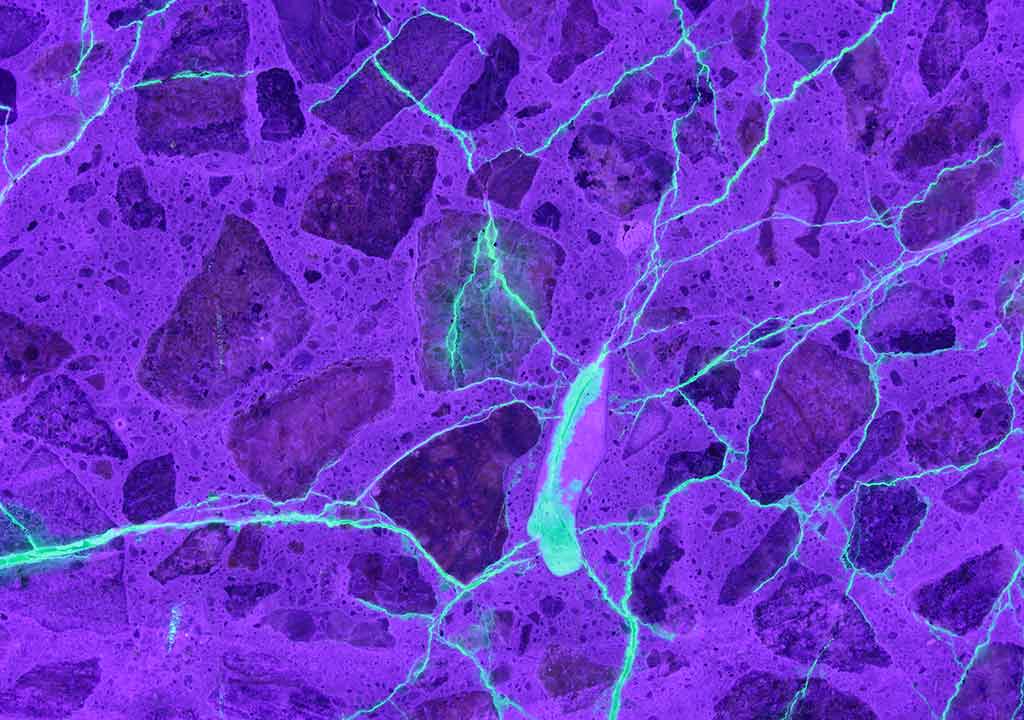

We have collected an extensive knowledge of the microstructure of concrete and related materials using optical fluorescence microscopy and scanning electron microscopy (SEM-EDX). Both methods are valuable tools when studying the concrete composition, degradation, and quality. Ability to master the microscopy tools and interpret the concrete microstructure will place your company ahead of competitors in the concrete technology business.

Our training courses focus on the use of optical fluorescent microscopy and SEM-EDX analysis and will targeted specifically of the pre-knowledge of the attendants. During the courses we make sure that attendants improve their skills in interpreting the micro-structural features observed and that they will be able to determine the concrete composition and estimate the mix design from a single concrete sample. We teach you the typical micro-structural features associated with different deterioration mechanisms as well as how to estimate the water to cement ratio by fluorescent thin section microscopy.

The courses offered may contain the following topics:

- The optical polarizing microscope, basic knowledge and use

- Optical fluorescent microscopy of concrete and related materials

- Point counting and estimation of concrete composition and strength

- Crack identification and interpretation

- Diagnosis of various deterioration mechanisms such as ASR, DEF, external and internal sulfate attack etc.

- Identification of carbonated and leached paste

- Determination of w/c ratio

- Errors & identification of preparation damages

- Preparation of fluorescent impregnated thin section

- The scanning electron microscope (SEM-EDX), basis knowledge and use

- Features observed by SEM, identification and interpretation

- Optical fluorescence microscopy & SEM-EDX – a powerful combination.

Typical length of a training course is 3-5 days. We will supply samples and teaching material; however, the attendants are encouraged to bring examples from you collection.

Besides teaching we further offers to supervise & coach for a longer period of time at your laboratory.

Remember, being capable of performing micro-structural analysis and understanding the features observed not only makes concrete analysis more fun, but also greatly increase the value of the product you deliver to your clients.

All services are provided by the Danish Technological Institute >

Other Services

In cooperation with Danish Technological Institute > we provide the following services

Terms and definitions

Using the same terms makes communication better! We have made this small dictionary which describes some of the terms used in concrete examination and description.

Terms and Definitions

The following small dictionary describes some of the terms used in concrete examination and description.

Agglomerate: 3 or more air voids in close contact

Aggregate: Component of the concrete consisting of a coarse aggregate fraction (more than 4 mm) and a fine aggregate fraction (less than 4 mm)

Alite: Tricalciumsilicate, C3S (3CaO-SiO2), a natural occurring mineral present in ordinary Portland cement.

Alkali silica reaction: Reaction between silica in the aggregates (e.g. chert, flint, micro-crystalline quartz), alkali (from cement, de-icing salt, sea water), calcium hydroxide and water. Alkali silica reaction causes aggregates to expand and cracks are formed radiating out into the ambient cement paste.

Alkali silica gel: A product of alkali silica reaction. Gel is usually clear, transparent and non-crystalline (amorphous), although in some cases it may crystallize. It expands during water absorption. Gel is usually found lining or filling cracks and air voids.

Aluminate phase: Tricalciumaluminate, C3A (3CaO-Al2O3)

Anhydrate: CaSO4

Belite: Dicalciumsilicate, C2S (2CaO-SiO2), natural occurring mineral present in ordinary Portland cement.

Bleeding: Water separation in the concrete. "Bleeding" is the phenomenon where water migrates towards the surface of the concrete and collects on the surface or underneath coarse aggregates. Seen as narrow voids along the interface between aggregate and cement paste. Calcium hydroxide may be deposited in the voids.

Calcium carbonate: CaCO3 , calcite, found as deposits in voids and cracks and on the surface.

Calcium hydroxide: Ca(OH)2, Portlandite, hydration product of C3S and C2S. Appears throughout the non-carbonated cement paste and occasionally as larger crystals in voids and cracks

Carbonation: Transformation of the calcium containing constituents of the concrete by reaction with the carbon dioxide in air. Calcium hydroxide is transformed to calcium carbonate and consequently the paste becomes chemically neutral.

Cement: The visible cement minerals are: C3S, C2S and C4AF. C3A is not visible.

Cement paste: Compound of hydration products from the cement-water reaction and unhydrated cement. Micro silica (MS) and fly ash (FA) is usually treated as part of the paste.

Cracks: Are divided in 3 groups in relation their width: coarse cracks are cracks wider than 0.1 mm, fine cracks varies from 0.01 - 0.1 mm and micro cracks are less than 0.01 mm. Cracks usually run in the cement paste; however, occasionally the aggregates are traversed. Cracks form either in the early (plastic stage) or at a later stage (fully hardened stage) in the life of the concrete .

Delayed Ettringite Formation (DEF): Hardened concrete that has been subjected to high-temperature heat curing or high internal hydration heat temperature may suffer from expansion and cracking during subsequent exposure to moisture. DEF is diagnosed by the presence of gaps around aggregate particles.

Entrained air: Usually defined as the small and medium sized spherical air voids with maximum size 0.5 - 1 mm

Entrapped air: Comprises irregular and angular air voids of all sizes

Ettringite: 3CaO.Al2O3.3CaSO4.32H2O. Needle shaped crystals of calcium sulfo-aluminate hydrate produced by constituents in the cement paste, including gypsum. It is also produced by sulfate attack on the concrete.

Ferrite phase: Tetracalciumaluminateferrite, C4AF (4CaO-Al2O3-Fe2O3)

Filled voids: Air voids with complete or partial filling of e.g. alkali silica gel, ettringite, calcium hydroxide, calcium carbonate or gypsum.

Friedel Salt (mono-chloride): 3CaO.Al2O3.CaCl2.10H2O

Gaps: Cracks observed all the way around aggregate particles in the interface zone between aggregate and cement paste. Gaps can be empty, or be partly or completely filled with ettringite. The width of the gaps is positively correlated with the size of the aggregate. Gaps are evidence of some sort of paste expansion occurring from delayed ettringite formation (DEF), freeze/thaw and sulfate attack.

Gypsum: CaSO4.2H2O, calcium sulfate which is found as a common constituent of cement. It is also produced by acid attack (sulfuric acid) on concrete.

Hydration: Reaction between cement and water, producing cement gel (cement paste, cement glue) serving as an adhesive in the concrete.

Mono-sulfate: 3CaO.Al2O3.CaSO4.12H2O

Plastic shrinkage: Shrinkage caused by strong drying of newly cast concrete. The result is often plastic shrinkage cracks in the concrete surface.

Plastic settlement: Settlement of fresh concrete, often causing plastic settlement cracks.

Re-crystallization: Dissolution of crystals and re-deposition either of the same mineral in a different form or of new minerals, mostly stabilized due to the presence of water.

Segregation: "Segregation" is the phenomenon where the concrete has no internal adhesion, and the mortar (therefore separates from the coarse aggregates.

Thaumasite: CaSiO3.CaSO4.CaCO3. A mineral not naturally present in concrete. Thaumasite may occur in concrete suffering from sulfate attack. The presence of thaumasite depends according to literature on temperature and presence of carbon dioxide.

w/c ratio: The ratio of water to cement by weight of the cement paste. If the cement paste contains fly ash (FA) or micro silica (MS) the addition of these materials can be taken into account using an activity factor and an equivalent w/c ratio can be calculated.

Contact Us

Concrete Experts International ApS

Gøngehusvej 242

DK-2950 Vedbæk