RapidAir 457

Automatic test of air void distribution in hardened concrete in less than 10 minutes in your laboratory

The RapidAir 457 equipment provides an automatic system for analyzing the air content in hardened concrete. The analysis time with the RapidAir 457 system is less than 10 minutes, which should be compared to the 4-6 hours normally required for manual analysis with conventional types of equipment.

The system can replace the manual test performed as described in the ASTM designation C457/C457M-16 procedure A, B and C “Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete” or the test performed according to EN 480-11 “Determination of air void characteristics in hardened concrete”. All methods include specifications for grinding, and polishing a plane section of concrete, and for measuring the air void distribution with the use of a microscope according to the linear traverse method and modified point count.

Advantages

- Increased productivity

- Operator independent

- Excellent repeatability

- Excellent reproducibility

- Good accuracy

Hardware and Software

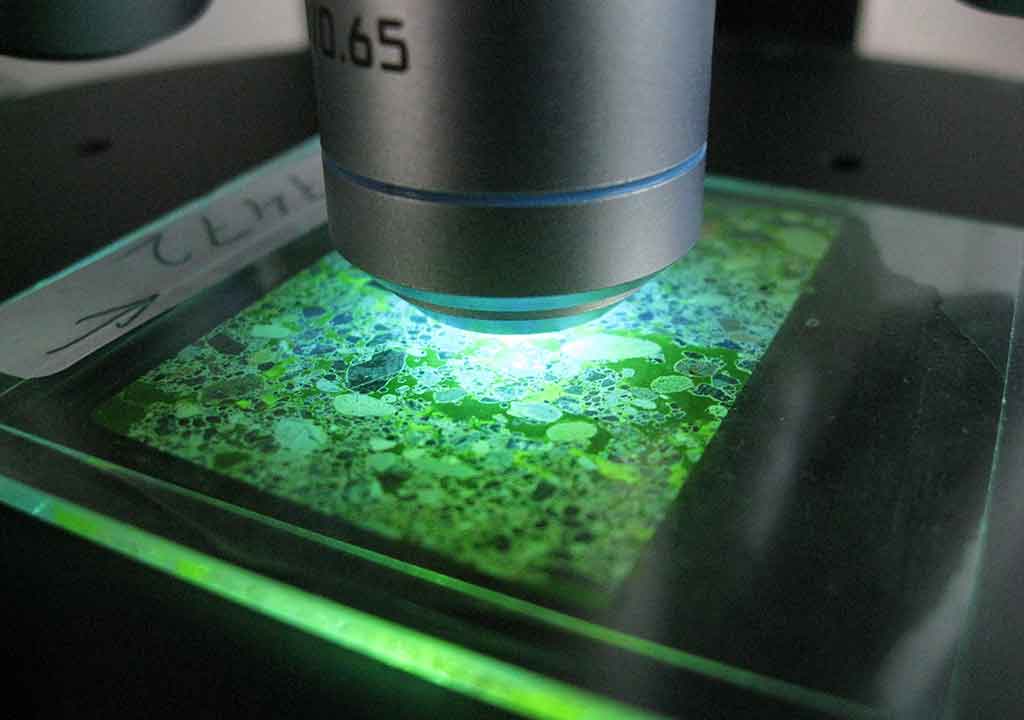

The RapidAir 457 test equipment consists of an automatic analysis system comprising a computerized control unit (PC) with a flat panel monitor, a digital camera, a microscope objective mounted on a moving stage, and a user friendly analysis software operating in a MS-Windows environment. The RapidAir 457 system has a resolution better than 2 microns, a magnification of about 100x, and is delivered pre-configured, aligned, tested, and ready for Plug-and-play use. The interface is user friendly allowing the daily operations to be handled in an easy and logical fashion that minimizes the risk of analysis or reporting errors.

Sample Preparation

Following the traditional grinding and polishing steps of ASTM C 457, a contrast enhancing technique (described in EN 480-11) is used to obtain a plane section surface where the air voids appear bright white, and the remaining surface appears black. Such a surface contrast facilitates maximum precision, and identification of all air voids present in the concrete sample. The time needed to perform a contrast enhancement is approximately 5 minutes. Since all preparation defects are addressed during the preparation procedure, the advantage of the contrast enhancement is that it eliminates the need for a “split second” human judgment, which is typically encountered during the normal manual type analysis.

Analysis

Following contrast enhancement, the plane section is mounted onto the moving stage that is positioned under the color digital camera. Choose either the ASTM or EN method and the analysis control unit now automatically moves the stage, and the air void distribution is determined from e.g. a typical ASTM scan of 1364 areas throughout the plane section (1364 areas provide a 2413 mm line of traverse as is required by ASTM C 457 for concrete with a 1″ maximum size aggregate).

The RapidAir software further allows the user to perform a semi-automatic point count according the ASTM procedure B.

Report Generation

After scanning the plane section, a report file (in MS-Excel format) is automatically saved. The operator can choose between compliant calculations according to ASTM C 457 and EN 480, between using SI and US units, and between letter size and A4 paper formats. In addition to the calculated air void parameters notably air content, specific surface area, and spacing factor, the report file also contains tabular as well as graphical presentations of the results of the air void analysis. The report file also contains a worksheet with the raw data in case the operator would like to perform additional user-specific calculations. At any time following the analysis, the report file can be printed or viewed from within the RapidAir user-friendly interface.

VIDEO: See the RapidAir 457 in action

Provided by one of our clients, gcp

RapidAir 457 advantages

- Increased productivity

- Operator independent

- Excellent repeatability

- Excellent reproducibility

- Good accuracy

Contact

Dr. Ulla H. Jakobsen

Tel +45 2835 0660

Client Testimonials

“It is a pleasure to recommend you to make use of Concrete Experts International’s

services. Their knowledge and experience is outstanding regarding new technology

developments with cement and concrete and related materials as well as for expert

investigations of the durability and deterioration of field concrete. The special, combined scientific-engineering experience makes the company a welcomed, consulting newcomer.”

“…On my behalf, as well as on behalf of my client, I want to thank all of you for the tremendous effort which you put forth in the case. You all did an excellent job. The work you did in a limited time period was first rate. I was particularly impressed with the high quality reports which you prepared.”

“…Thanks for all your help in the case. Your experience, research and testimony were

very important and critical to the successful outcome. These cases are always complex, but by having the right experts, we greatly improved our defense.”

Terms and definitions

Using the same terms makes communication better! We have made this small dictionary which describes some of the terms used in concrete examination and description.

Terms and Definitions

The following small dictionary describes some of the terms used in concrete examination and description.

Agglomerate: 3 or more air voids in close contact

Aggregate: Component of the concrete consisting of a coarse aggregate fraction (more than 4 mm) and a fine aggregate fraction (less than 4 mm)

Alite: Tricalciumsilicate, C3S (3CaO-SiO2), a natural occurring mineral present in ordinary Portland cement.

Alkali silica reaction: Reaction between silica in the aggregates (e.g. chert, flint, micro-crystalline quartz), alkali (from cement, de-icing salt, sea water), calcium hydroxide and water. Alkali silica reaction causes aggregates to expand and cracks are formed radiating out into the ambient cement paste.

Alkali silica gel: A product of alkali silica reaction. Gel is usually clear, transparent and non-crystalline (amorphous), although in some cases it may crystallize. It expands during water absorption. Gel is usually found lining or filling cracks and air voids.

Aluminate phase: Tricalciumaluminate, C3A (3CaO-Al2O3)

Anhydrate: CaSO4

Belite: Dicalciumsilicate, C2S (2CaO-SiO2), natural occurring mineral present in ordinary Portland cement.

Bleeding: Water separation in the concrete. "Bleeding" is the phenomenon where water migrates towards the surface of the concrete and collects on the surface or underneath coarse aggregates. Seen as narrow voids along the interface between aggregate and cement paste. Calcium hydroxide may be deposited in the voids.

Calcium carbonate: CaCO3 , calcite, found as deposits in voids and cracks and on the surface.

Calcium hydroxide: Ca(OH)2, Portlandite, hydration product of C3S and C2S. Appears throughout the non-carbonated cement paste and occasionally as larger crystals in voids and cracks

Carbonation: Transformation of the calcium containing constituents of the concrete by reaction with the carbon dioxide in air. Calcium hydroxide is transformed to calcium carbonate and consequently the paste becomes chemically neutral.

Cement: The visible cement minerals are: C3S, C2S and C4AF. C3A is not visible.

Cement paste: Compound of hydration products from the cement-water reaction and unhydrated cement. Micro silica (MS) and fly ash (FA) is usually treated as part of the paste.

Cracks: Are divided in 3 groups in relation their width: coarse cracks are cracks wider than 0.1 mm, fine cracks varies from 0.01 - 0.1 mm and micro cracks are less than 0.01 mm. Cracks usually run in the cement paste; however, occasionally the aggregates are traversed. Cracks form either in the early (plastic stage) or at a later stage (fully hardened stage) in the life of the concrete .

Delayed Ettringite Formation (DEF): Hardened concrete that has been subjected to high-temperature heat curing or high internal hydration heat temperature may suffer from expansion and cracking during subsequent exposure to moisture. DEF is diagnosed by the presence of gaps around aggregate particles.

Entrained air: Usually defined as the small and medium sized spherical air voids with maximum size 0.5 - 1 mm

Entrapped air: Comprises irregular and angular air voids of all sizes

Ettringite: 3CaO.Al2O3.3CaSO4.32H2O. Needle shaped crystals of calcium sulfo-aluminate hydrate produced by constituents in the cement paste, including gypsum. It is also produced by sulfate attack on the concrete.

Ferrite phase: Tetracalciumaluminateferrite, C4AF (4CaO-Al2O3-Fe2O3)

Filled voids: Air voids with complete or partial filling of e.g. alkali silica gel, ettringite, calcium hydroxide, calcium carbonate or gypsum.

Friedel Salt (mono-chloride): 3CaO.Al2O3.CaCl2.10H2O

Gaps: Cracks observed all the way around aggregate particles in the interface zone between aggregate and cement paste. Gaps can be empty, or be partly or completely filled with ettringite. The width of the gaps is positively correlated with the size of the aggregate. Gaps are evidence of some sort of paste expansion occurring from delayed ettringite formation (DEF), freeze/thaw and sulfate attack.

Gypsum: CaSO4.2H2O, calcium sulfate which is found as a common constituent of cement. It is also produced by acid attack (sulfuric acid) on concrete.

Hydration: Reaction between cement and water, producing cement gel (cement paste, cement glue) serving as an adhesive in the concrete.

Mono-sulfate: 3CaO.Al2O3.CaSO4.12H2O

Plastic shrinkage: Shrinkage caused by strong drying of newly cast concrete. The result is often plastic shrinkage cracks in the concrete surface.

Plastic settlement: Settlement of fresh concrete, often causing plastic settlement cracks.

Re-crystallization: Dissolution of crystals and re-deposition either of the same mineral in a different form or of new minerals, mostly stabilized due to the presence of water.

Segregation: "Segregation" is the phenomenon where the concrete has no internal adhesion, and the mortar (therefore separates from the coarse aggregates.

Thaumasite: CaSiO3.CaSO4.CaCO3. A mineral not naturally present in concrete. Thaumasite may occur in concrete suffering from sulfate attack. The presence of thaumasite depends according to literature on temperature and presence of carbon dioxide.

w/c ratio: The ratio of water to cement by weight of the cement paste. If the cement paste contains fly ash (FA) or micro silica (MS) the addition of these materials can be taken into account using an activity factor and an equivalent w/c ratio can be calculated.

Contact Us

Concrete Experts International ApS

Gøngehusvej 242

DK-2950 Vedbæk